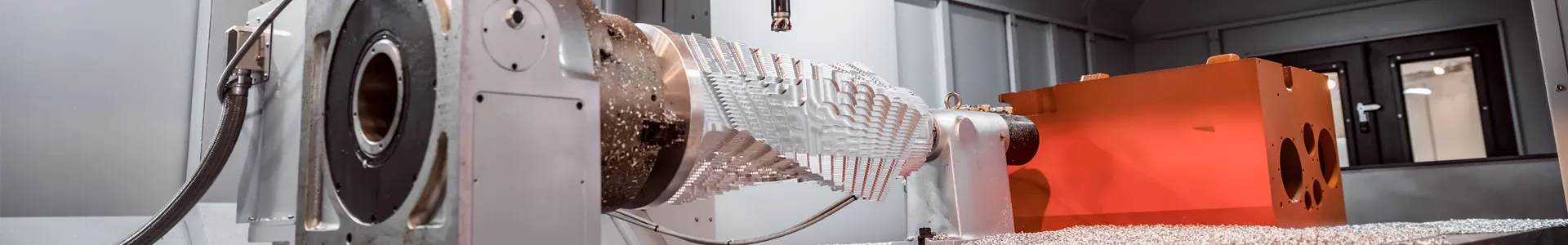

BS-TSC-150IA

The thermal shock test chambers of this series are one of the commonly used devices in various environmental tests. They are suitable for electronic instruments and meters, materials, electrical engineering, vehicles, metals, aviation products, electronic products